Factory Show

|

|

|

| The razor wire material galvanized steel coils

|

Material steel wire rope

|

|

|

|

|

|

cutting galvanized steel coils to barbed tape |

cutting galvanized steel coils to barbed tape |

|

|

|

|

|

|

|

|

|

|

Forming razor wire |

After cutting razor barbed tape tightly crimped around the steel wire rope |

|

|

|

|

|

|

|

|

|

|

Razor wire packing with into hard cartoon boxes |

Packing inside is water proof paper and outside is woven bags and then loading into hard cartoon boxes. |

|

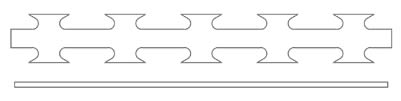

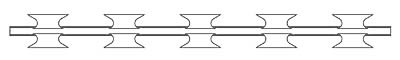

Razor Concertina Wire manufactured by the following technologies. First, rolled galvanized steel coils by cold forging, made barbed tape - a metal band with a sharp cutting studs on both sides. Then, barbed tape on special equipment is crimped around the guide wire. As Aiming high carbon wire is commonly used spring wire. After crimping get razor wire concertina barbed tape, concertina barbed tape is practically one with the foundation, it can not in any way be separated from the carrier wire. The following two images are the barbed tape and steel wire state of before crimped and after crimping.

Concertina razor wire is produced by modern automatic stamping complex of high quality materials that meet the required standards. Razor barbed tape manufactured by cold forming from galvanized steel coils with a thickness of 0.55 mm and galvanized high carbon spring rope wire or cable with a diameter of 2.5 mm.

Materialsú║

Steel Wire rope is made with a diameter of 0.2 to 4.0 mm, uncoated and galvanized. Rope wire is available in different thickness of the zinc coating - for medium and hard working conditions, in addition, cable wires on the mechanical properties divided by the highest and the first category. Our razor wire made of steel wire rope of the highest category with a zinc coating, designed for operation in harsh environments. Galvanized steel wire is intended for the manufacture of steel-aluminum, non-insulated cores and wires. Galvanized steel wire produced with diameters from 1.85 to 4.5 mm. Galvanized steel wire are made of three classes on the mechanical properties and the thickness of the two types of zinc coatings. Our razor barbed wire made from galvanized steel wire with maximum parameters - the ultimate tensile strength and thickness of the zinc coating.

Our razor barbed wire is manufactured only from high quality materials and the relevant rules. Barbed tape concertina is made of galvanized steel coils. In the manufacture of razor wire, we use galvanized steel coil thickness of 0.5 ... 0.59 mm for cold forming with uniform zinc coating.

All materials for the manufacture of razor fences and spiral razor have a protective zinc coating of sufficient thickness, and manufacturing technology to avoid damage to the surface during molding and compressing. By this means the life of our razor mesh fence is several times longer than standard razor wire.

The starting materials for razor production are galvanized steel strip, galvanized steel wire rope or spring, which has high strength and resilient properties, as well as haywire or steel strip for the manufacture of staples in the spiral obstacles production. The quality of raw materials largely determines the quality of razor wire concertina.By cold forming from galvanized steel strip is produced with cutting tape located on both sides of studs having sharp cutting edges. After cutting this tape tightly crimped around the base - high carbon steel galvanized wire, this gives a little one-piece construction, no backlash and surface defects - concertina wire.

Concertina razor fencing in this form has sufficient barrier properties, but its efficiency is much enhanced if it is used in the form of spiral obstacles. The spiral of razor concertina wire, also called spiral security barrier concertina, is produced by razor barbed wire twist on the principle of a spiral, resulting in a volumetric spiral design, which has the highest protective properties.